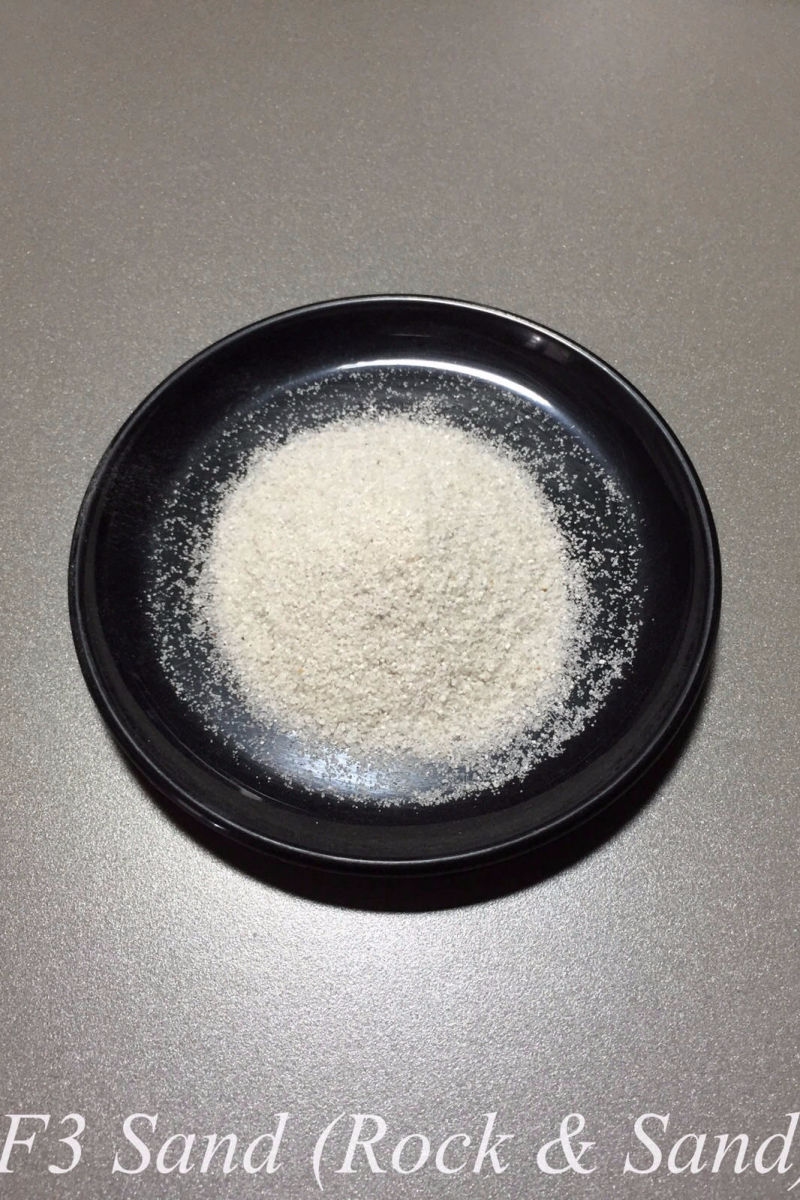

Media Filtration

Silica sand is used frequently in water filtration systems where it is the primary filtration medium to extracts solids from contaminated water. Filter silica sand consists of hard, durable, and dense grains of predominantly siliceous material that will resist degradation during handling and use.